How Professional Electrical Maintenance Reduces Downtime

Downtime can disrupt productivity, delay customer service, and cost businesses significant revenue. One of the most effective ways to prevent these interruptions is through professional Electrical maintenance. When trained technicians inspect, diagnose, and optimize your electrical systems regularly, potential failures are caught long before they can shut down operations. At PM Electric, we know how essential proactive care is for keeping businesses running efficiently. This guide explains how professional Electrical maintenance reduces downtime and helps you maintain a safe, productive environment.

Why Downtime Happens in the First Place

Equipment Overload and Stress

When circuits are overloaded or equipment doesn’t receive stable power, breakdowns become inevitable. Without consistent Electrical maintenance, these power issues remain hidden until they cause a shutdown. Professional inspections ensure your system can handle current demands without straining essential equipment.

Undetected Wear and Tear

Electrical components age over time. Wiring loosens, breakers weaken, and panels collect dust. If these issues go unnoticed, they eventually lead to failures that interrupt business operations. Professional Electrical maintenance identifies component fatigue early, allowing you to fix small problems before they become expensive disruptions.

Power Quality Issues

Voltage spikes, dips, and imbalances can damage sensitive equipment. Professional Electrical maintenance ensures your system delivers stable, reliable power to support daily operations without interruption.

How Professional Maintenance Minimizes Downtime

Early Identification of Problems

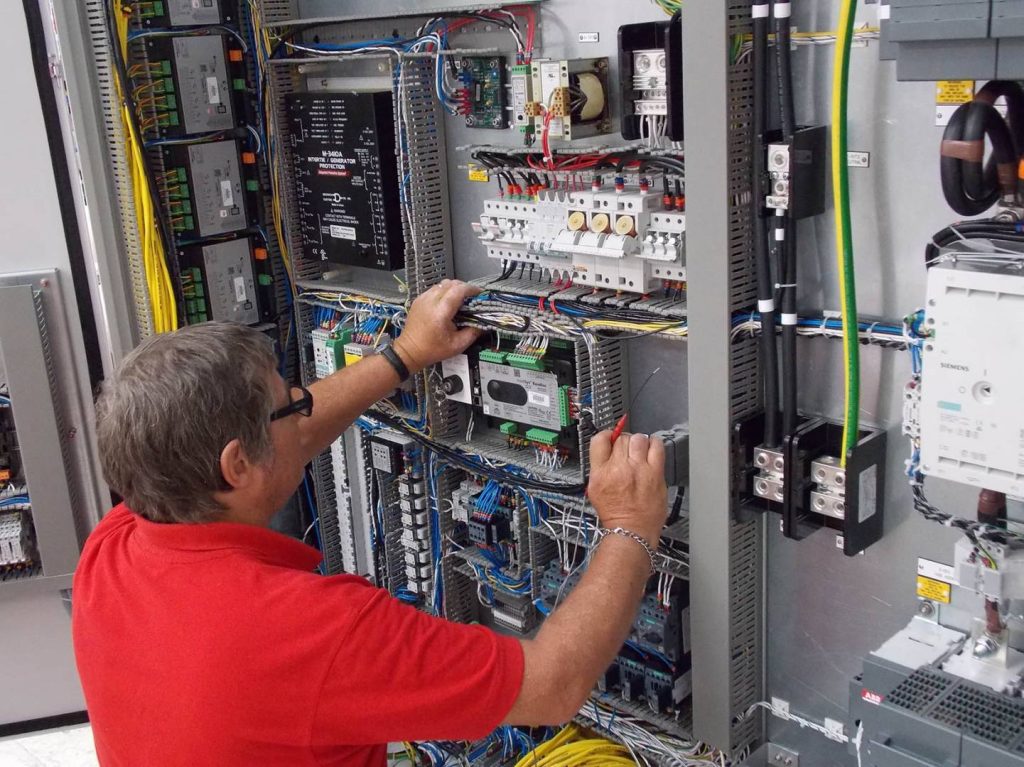

The earlier a problem is found, the easier and cheaper it is to fix. Through regular Electrical maintenance, technicians use tools and testing methods to detect excessive heat, loose connections, or weakening components long before they cause downtime.

Making Repairs Before Failures Occur

Preventative action is far more efficient than waiting for equipment to fail. Professional Electrical maintenance addresses issues immediately, preventing sudden outages that can halt operations for hours or days.

Ensuring Optimal System Performance

A well-maintained system performs better and more reliably. During Electrical maintenance, technicians clean, tighten, test, and calibrate essential components, reducing system stress and enhancing overall performance.

Key Elements of Professional Electrical Maintenance That Reduce Downtime

Comprehensive System Inspections

Experts examine panels, wiring, conduits, outlets, lighting, and grounding systems. This thorough Electrical maintenance approach ensures no weak point is overlooked—one small fault can be enough to trigger an unexpected shutdown.

Load Balancing and Circuit Optimization

Unbalanced loads can lead to tripped breakers and system failures. With professional Electrical maintenance, technicians analyze and rebalance circuits to ensure all equipment receives the right amount of power without overload.

Panel and Breaker Testing

Breaker failures are one of the leading causes of downtime. Professional Electrical maintenance includes testing breakers for responsiveness, ensuring panels remain clean, and confirming all connections remain tight.

Equipment Compatibility Checks

As businesses grow or upgrade machinery, electrical demands shift. Professional Electrical maintenance verifies that new equipment is compatible with your existing system to prevent overloads or failures.

Safety Device Verification

Emergency lighting, surge protectors, and interruption devices must work flawlessly. These components are tested during professional Electrical maintenance to ensure they respond correctly during unexpected power disturbances.

The Business Benefits of Professional Maintenance

Lower Repair Costs

Emergency repairs during downtime are far more expensive than routine Electrical maintenance. By catching issues early, businesses save money and avoid unnecessary operational delays.

Better Productivity and Workflow

When power remains stable and equipment works reliably, employees stay productive. Professional Electrical maintenance minimizes disruptions so your team can stay focused on their tasks.

Longer Equipment Lifespan

If equipment receives clean, balanced power, it lasts longer. Professional Electrical maintenance protects valuable machinery and extends service life, reducing the frequency of replacements.

Improved Safety

Electrical failures can cause fires, shocks, and hazardous conditions. Routine Electrical maintenance identifies these dangers early, protecting employees and customers while keeping your facility compliant.

Creating a Downtime-Reduction Plan Through Professional Maintenance

Schedule Regular Service

Consistency is the key to successful Electrical maintenance. Monthly, quarterly, and annual inspections allow businesses to maintain a strong, dependable electrical system year-round.

Keep Detailed Records

Tracking repairs, inspections, and upgrades helps technicians understand long-term patterns. Documenting your Electrical maintenance history allows for better planning and faster troubleshooting.

Partner With Trusted Professionals

Your facility deserves expert care. PM Electric provides specialized Electrical maintenance programs tailored to the specific needs of commercial operations. With experienced technicians, advanced tools, and customized plans, your business stays protected from unexpected disruptions.

Conclusion

Professional Electrical maintenance is one of the most effective ways to reduce downtime and ensure the long-term reliability of your electrical systems. By identifying problems early, optimizing performance, and protecting equipment, trained technicians help keep your business running smoothly and safely. Partnering with experts like PM Electric ensures your facility receives the preventative care it needs to stay productive. Start prioritizing Electrical maintenance today to minimize downtime, protect your investments, and maintain uninterrupted operations across your entire facility.